Company Profile

Chintek Technology was established in Oct 1992 and currently operates one plant in Taiwan encompassing more than 120 employees. We locate in Zhong He District, New Taipei City, where are the important area within many important suppliers and customers in Information Technology Manufacturing. Our location is also near by the transportation hub of freeway to international airport, HSR (high speed railway) and MRT (metro railway transportation).

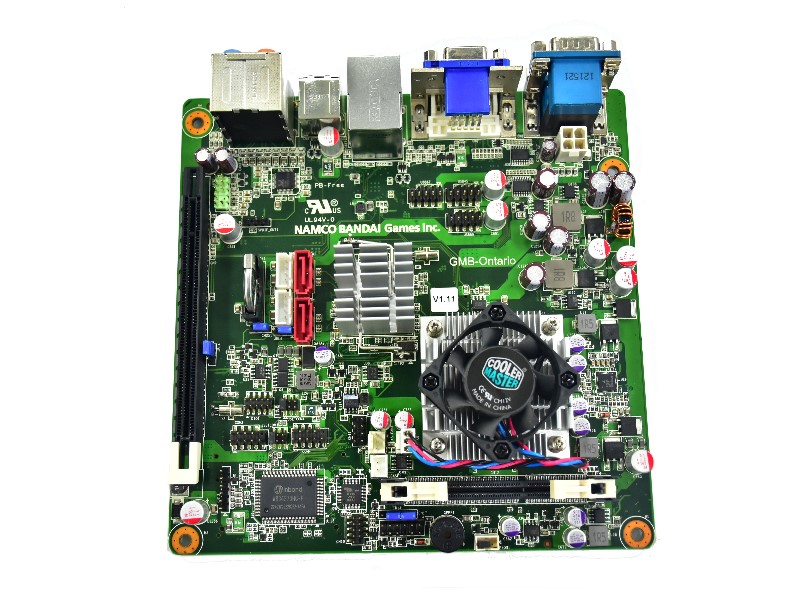

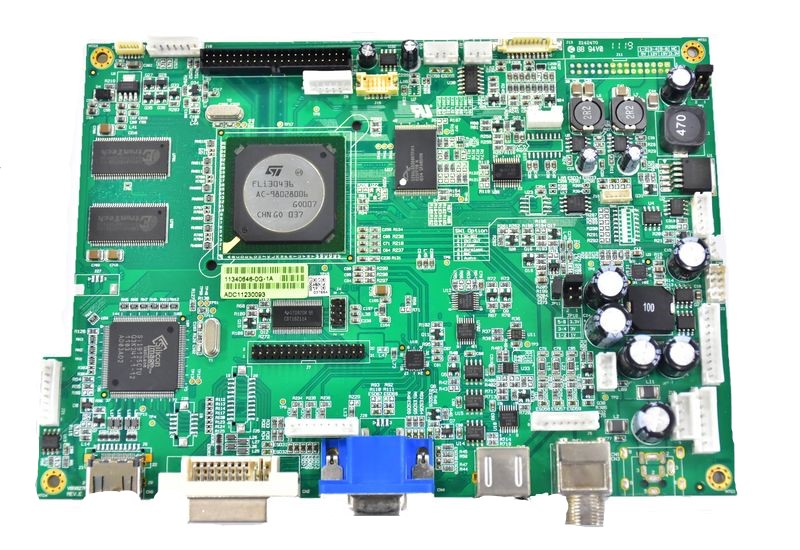

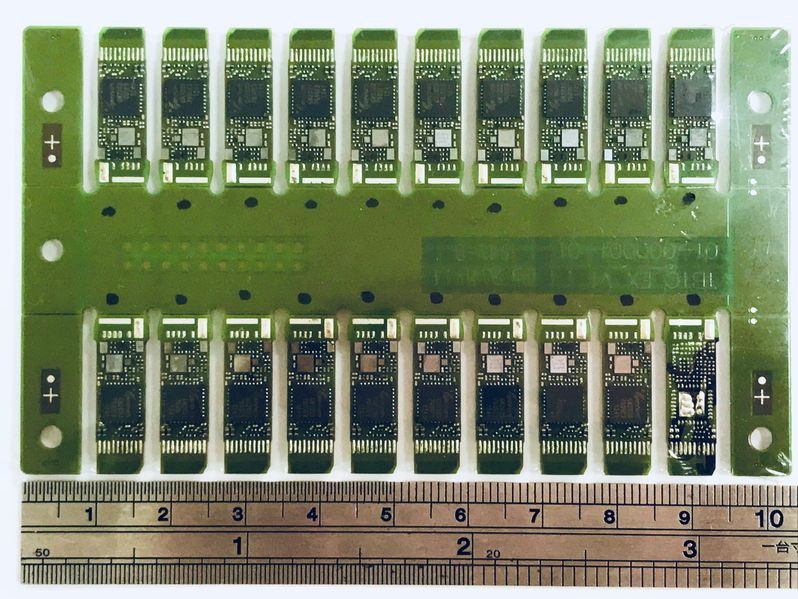

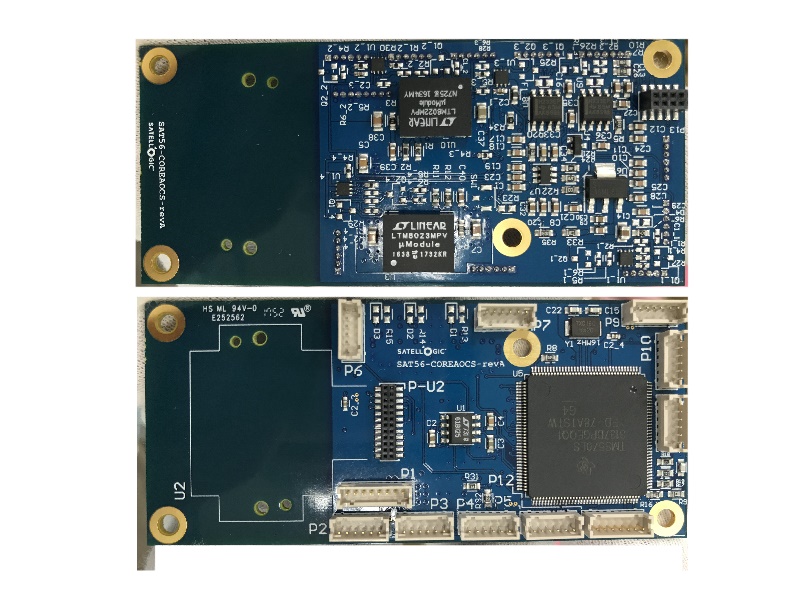

As a professional EMS company (electronics manufacturing service), we provide all process you will need in production, including SMT mounting, DIP/through hole process, hand soldering, board testing, system burn-in, system assembly, system testing and packaging. Our customers can get our support from engineering data modification, component purchasing, PCBA, warehouse stocking and shipping. Our customers are always satisfied by our rapid and efficient response.

Our flexible system could satisfy our customers in NPI (new product introduction), trail run and sample run. The transparent quotation system will help our customers to get the fair cost in mass production. We focus on our customer need and to provide our customers a tailor made experience in EMS.